Grinding Wheels

Filters >>

Filters >>

Narrow it Down!

Ohio Power Tool supplies a lot of workshops and factories who rely heavily on grinding for various metalworking tasks. But with a vast array of grinding wheel types available, choosing the right one ensures efficient work and a flawless finish. Here's a breakdown of the most common grinding wheels and their ideal applications:

Type 27 Grinding Wheels: These are the undisputed champions of versatility. They feature a flat profile with a depressed center, allowing for clearance when grinding at an angle. Type 27 wheels come in various sizes and abrasive grits, making them suitable for a wide range of tasks. Coarser grit wheels excel at stock removal, like grinding down welds or shaping thick metal stock. Finer grit wheels create a smoother surface finish, ideal for final touches or preparing surfaces for further machining. Their adaptability makes type 27 wheels a staple in any Ohio metalworking environment.

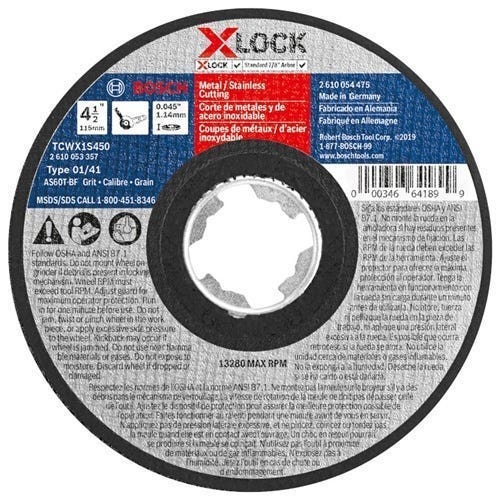

Specialty Grinding Wheels: Beyond the versatile type 27 wheel, the grinding world offers specialized options for specific applications. Cut-off wheels are thin, reinforced discs designed for aggressive cutting of metal bars, pipes, or sheet metal. They prioritize fast cutting over a smooth finish, making them ideal for quick material separation tasks. Snagging wheels feature a recessed center and a coarse abrasive grit. They excel at removing heavy rust, paint, or scale from metal surfaces, perfect for cleaning up neglected or heavily oxidized workpieces commonly encountered in restoration projects. Polishing wheels utilize very fine abrasives or even cloth buffs to achieve a mirror-like finish on metals, often the finishing touch for decorative or high-precision parts.

Considering Material and Shape: While selecting the appropriate abrasive grit is crucial, material compatibility and wheel shape also play a role. Aluminum oxide wheels are a popular choice for general-purpose grinding on mild steel or soft metals. Zirconia alumina wheels offer superior performance on harder metals like stainless steel or tool steel. For specific tasks, the wheel shape can be vital. Depressed center wheels provide better access when grinding in tight spaces or along corners. Cup wheels with a recessed center are ideal for grinding curved surfaces or cleaning out welds.

By understanding the capabilities of type 27 wheels, specialty options, and the importance of material compatibility and shape, metalworkers can choose the perfect grinding wheel for any application. The right wheel ensures efficient material removal, a beautiful finish, and keeps your metalworking projects on track for success.